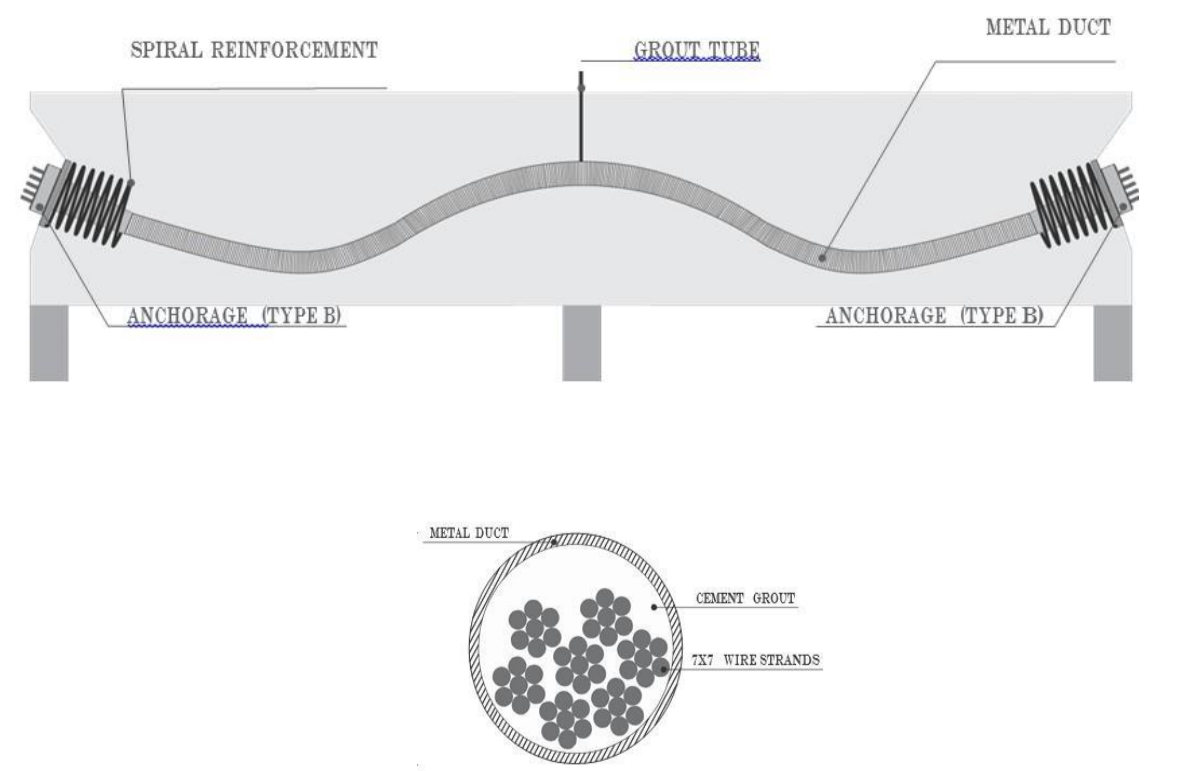

BONDED POST-TENSIONING SYSTEM

The bonded post-tensioned system in whom the tendons are positioned inside a metal duct, thus ensuring insulation between the tendons and the concrete.

Adhesion in turn occurs after concreting, when the cement cream is injected inside the

metal duct, for its complete filling, thus reestablishing the contact between concrete and steel.

The purpose of this step is to effectively guarantee the corrosion protection of the reinforcement of post-tension, in addition to guaranteeing

the mechanical adhesion to the concrete throughout the extension of the cable. By applying pretension to the strands, internal stresses are created, thus fighting loads resulting from loading and improving structure performance.

The bonded

post-tensioning guarantees protection to the structure and its users, as it allows the integration between the reinforcement of the concrete and the concrete, in order to work together. In this way, the struts are constantly stretched throughout

the useful life of the structure and if tendon is to be cut or broken, the structure will have the capacity to absorb the stresses resulting from this break.

In this system there is the possibility of the struts being placed in the tendons

before or after the concreting process, allowing, for example, that prefabricated elements unite by means of the pretension. In addition, the bonded post-tensioning system presents greater resistance if subjected to fire.

TENDONS SPECIFICATIONS

The bonded post-tensioned system uses tendons typically based on the use of 270ksi (1860MPa), 7 wire. In post-tensioning applications where the cables are in bond with concrete, the diameter of the cable can be as much as 0.5 inches (12.7mm) as 0.6 inches (15.2mm).

ANCHORAGE MONO AND MULTI-STRAND SYSTEM

The anchors are devices whose function is to fix the pretension tendons, in order to keep them in a state of tension, causing the posttension force to be transmitted to the concrete. That is, the anchors have the role of preventing that once tensioned the string returns to its original state, in this case, without tension.

MONO ANCHOR SYSTEM

Used in the construction of elevated slabs, raft foundation, slabs on grade, warehouses, distribution centers, container terminals, airports, pavements, residential slabs and recreational slabs. For tennis courts and skating rings are common applications .

MULTI-STRAND ANCHOR

In order to offer arange of small tendons with flat anchors especially adapted to post-tensioning of buildings or thin elements (slabs, floors). This system is particularly adapted to the applications with threading of the strand after concreting.

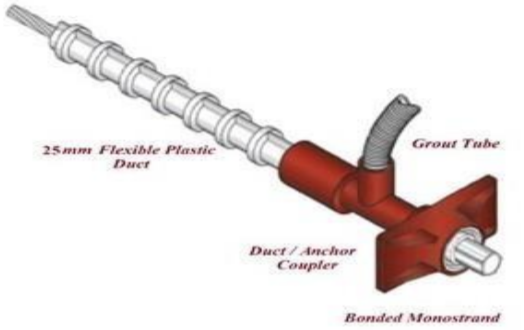

PLASTIC CORRUGATED PIPES (USED FOR BONDED SYSTEM)

The corrugated pipes are defined basically by ducts, metal or plastic, being able to be rigid or flexible and it has the function of protecting and isolating the tendon of the exterior concrete, besides making possible the movement of same during the post-tension and subsequently receiving in the cement cream in the action of injection.

Coils / Strands: 12.70mm and/or 15.24mm

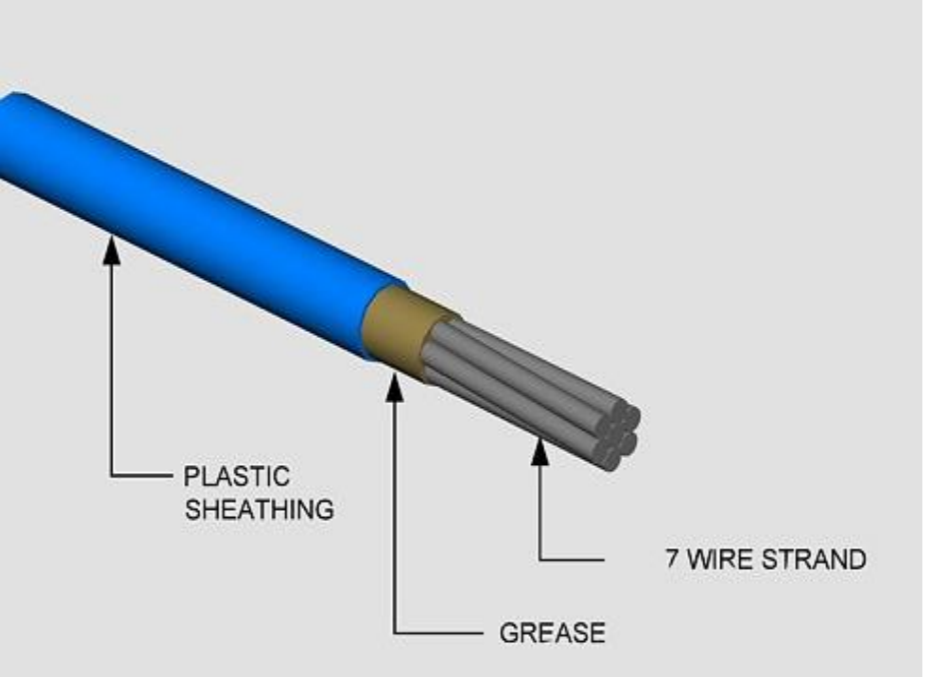

UNBONDED POST-TENSIONING SYSTEM

Concrete (in-situ) is poured first, and cables are stressed after concrete attained a specified compressive strength. One of the Internal Post-Tensioning Systems is Unbonded post-tensioning system – single (mono) strands coated with a corrosion-inhibiting

coating protected by extruded plastic sheathing. Almost all post-tensioned building construction utilizes unbonded tendons.

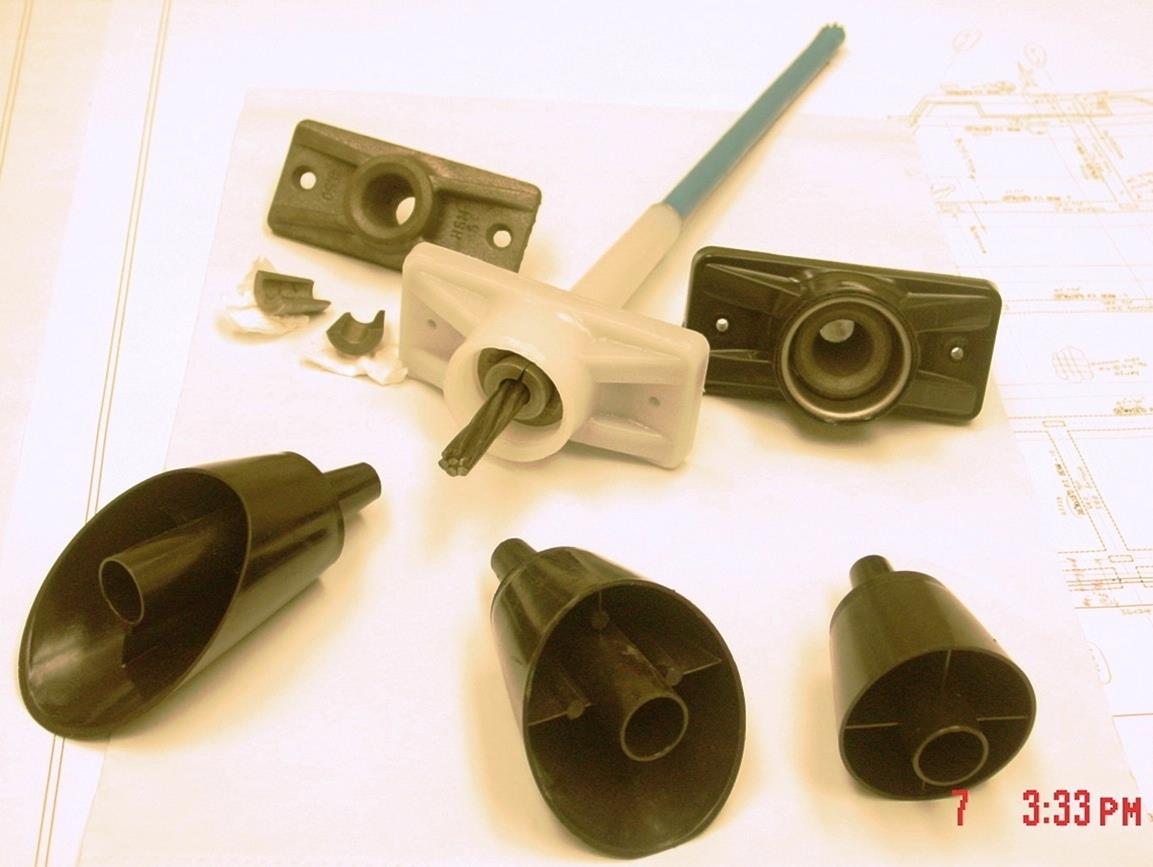

- Basic Components of Unbonded mono-strand Post-Tensioning System

- Extruded cables

-Anchors and Wedges

- Corrosion protection of Unbonded mono-strand

- Corrosion protection in unbonded tendons is provided by a factory-applied corrosion inhibiting coating material and extruded plastic sheath.

-In highly aggressive corrosive environments, the tendon can be completely encapsulated.

- Unbonded Mono-strand Anchorages

- Standard non-encapsulated system

-Encapsulated (CPS*) system

Standard Non-encapsulated system

Assembled encapsulated mono-strand tendon

CPS Corrosion Protection System

Some Of LTC Equipments

Mono-strand stressing jack

Onion jack

Mono-strand electric pump

Grouting Machin